Termin-8 Presentation (Feed & Feed Ingredients)

FEED IS YOUR LARGEST INVESTMENT... Safeguard it with Protecting feed ingredients and finished feed against bacterial and viral contamination Explore Now

Visualizing Risk of Feed Source Pathogens Independent research confirms feed as a fomite for bacterial pathogens such as Salmonella and viral pathogens such as HPAI. Transmission risk varies across the production chain, dependent on the raw materials used, environmental conditions faced and the presence of legacy bacteria in feed and feed ingredient production systems. It’s easy to see why a single-step intervention, without proper recontamination protection, fails to reliably address the challenge. Cropping Ingredient processing/logistics Milling (storage, grinding, mixing, pelleting and cooling) On-farm & in feeders Food processing Profiling based on raw material risk (Richardson et al 2000, legacy bacteria in feed milling (Gosling et al 2022), on farm (Alali and Ricke 2012) and in food processing (EFSA 2022)

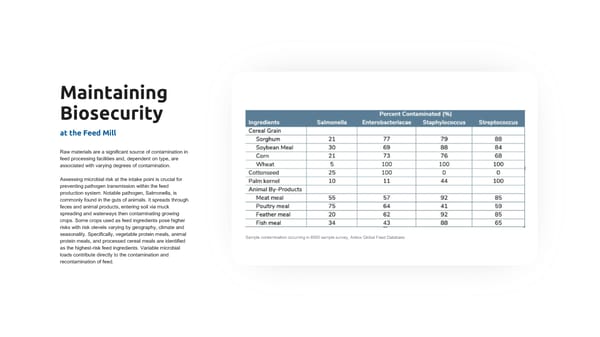

Maintaining Biosecurity at the Feed Mill Raw materials are a significant source of contamination in feed processing facilities and, dependent on type, are associated with varying degrees of contamination. Assessing microbial risk at the intake point is crucial for preventing pathogen transmission within the feed production system. Notable pathogen, Salmonella, is commonly found in the guts of animals. It spreads through feces and animal products, entering soil via muck spreading and waterways then contaminating growing crops. Some crops used as feed ingredients pose higher risks with risk olevels varying by geography, climate and seasonality. Specifically, vegetable protein meals, animal Sample contamination occurring in 8000 sample survey, Anitox Global Feed Database protein meals, and processed cereal meals are identified as the highest-risk feed ingredients. Variable microbial loads contribute directly to the contamination and recontamination of feed.

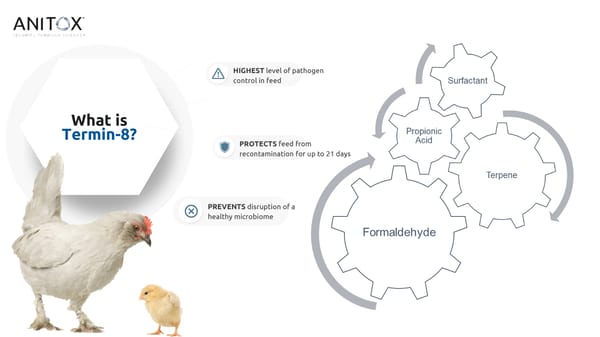

HIGHEST level of pathogen control in feed What is Termin-8? PROTECTS feed from recontamination for up to 21 days PREVENTS disruption of a healthy microbiome

Uniform Termin-8 is a application synergistic blend Surfactant and terpene within the Broad spectrum Each ingredient enhances the formulation aid in the uniform control efficacy of its counterparts. application and disruption of cellular walls. Formaldehyde and Synergism within the formulations propionic acid interrupt critical gives Termin-8 broad spectrum cellular function leading to cell control against molds, yeast and death. bacteria.

For Feed and Feed Ingredients Field Trial Background: A commercial mill producing breeders' diets in the Caribbean faced constant pressure to remain compliant with strict Salmonella standards. The mill was already routinely treating breeder feeds with a feed sanitizer. However, other feeds manufactured in the mill are not treated. After an initial investigation, mill management found that untreated feed led to Salmonella contamination of feed-facing areas. As a result, the Salmonella prevalence within the feed production areas of the mill was 10.16%. Feed Treatment: A biweekly 3-ton flush of wheat midds treated with Termin-8 was implemented to sanitize the mixer and post-batching systems (conveyors and elevators, bins). Application: 24 lb/ton Observations: Environmental Salmonella prevalence within the mill decreased and the feed contamination risk was significantly reduced. Implementation of biweekly flushes effectively sanitized feed-facing milling equipment. Salmonella risk was reduced by approximately 64%.