Anitox Multi-Point Intervention Programs

FOLLOWING THE SCIENCE BEHIND... Clean Feed for Productivity Protecting feed ingredients and finished feed with a tailored formulation to maximize efficient animal production. GET STARTED

Visualizing Risk of Salmonella Independent research confirms Salmonella risk varies across the production chain, dependent on the raw material involved, environmental conditions and the likely presence of legacy bacteria. It’s easy to see why a single-step intervention, without proper recontamination protection, fails to reliably address the challenge. Cropping Ingredient processing/logistics Milling (storage, grinding, mixing, pelleting and cooling) On-farm & in feeders Food processing Profiling based on raw material risk (Richardson et al 2000, legacy bacteria in feed milling (Gosling et al 2022), on farm (Alali and Ricke 2012) and in food processing (EFSA 2022)

Visualizing the Impact of M-PIPs on Salmonella Risk Anitox Multi-Point Intervention Programs (M-PIPs) take a scientific approach to feed safety, focusing interventions where risk is greatest. M-PIP value lies in its ability to help producers use less chemical more efficiently. M-PIP flexibility allows producers to maintain control over microbial levels and adjust the program as needed to maintain standards. Cropping Ingredient processing/logistics Milling (storage, grinding, mixing, pelleting and cooling) On-farm & in feeders Food processing Profiling based on raw material risk (Richardson et al 2000, legacy bacteria in feed milling (Gosling et al 2022), on farm (Alali and Ricke 2012) and in food processing (EFSA 2022)

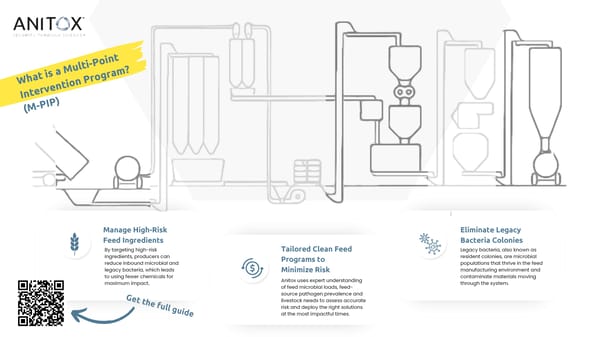

t n i o P - i t l u ? M a m a s i r g t o a r h P W n o i t n e v r e t n I ) P I P - M ( Eliminate Legacy Manage High-Risk Bacteria Colonies Feed Ingredients By targeting high-risk Legacy bacteria, also known as Tailored Clean Feed ingredients, producers can resident colonies, are microbial Programs to reduce inbound microbial and populations that thrive in the feed legacy bacteria, which leads manufacturing environment and Minimize Risk to using fewer chemicals for contaminate materials moving Anitox uses expert understanding maximum impact. through the system. of feed microbial loads, feed- source pathogen prevalence and G e livestock needs to assess accurate t t h e f u risk and deploy the right solutions l l g u i d at the most impactful times. e

Anitox: Trusted by the World’s Leading Food Producers COST EFFECTIVE SALMONELLA CONTROL USED AT LOW INCLUSION RATES ON FINISHED GOODS MITIGATES INBOUND MICROBIAL LOADS LONG-TERM PROTECTION AGAINST RECONTAMINATION REDUCES RISK OF INTRODUCING PATHOGENS INTO THE EFFECTIVE FLUSHING TO REDUCE AND ELIMINATE PRODUCTION PROCESS LEGACY BACTERIA 65% €140k 2x Chemical Reduction in Annual Savings ROI Annually

About Finio Used at low inclusion rates on finished goods Offer long-term protection against recontamination And, for high-dose application to flushing materials, effectively reduce legacy bacteria Finio is a market leader in feed sanitation exhibiting a high level of control for Salmonella in feed and feed ingredients. Finio protects feed and feed ingredients from recontamination for at least 14 days at low inclusion. Independent trials conducted by Animal Plant and Health Agency (APHA) found that at 2 kg/MT Finio controls Salmonella in feed more effectively than commercial organic acid blends used at 6 kg/MT.

About Fortrol Cost-effective Salmonella control Mitigates inbound microbial loads Reduces the risk of introducing pathogens into the production process Fortrol is a synergistic blend of organic acids that has been shown to provide dose-dependent control of Salmonella in feed. Fortrol can be tailored to meet producer needs based on the microbial challenge presented. When tested at intervals between 2 and 8 kg/MT a more significant Salmonella reduction was observed with each consecutive kilogram per metric ton.